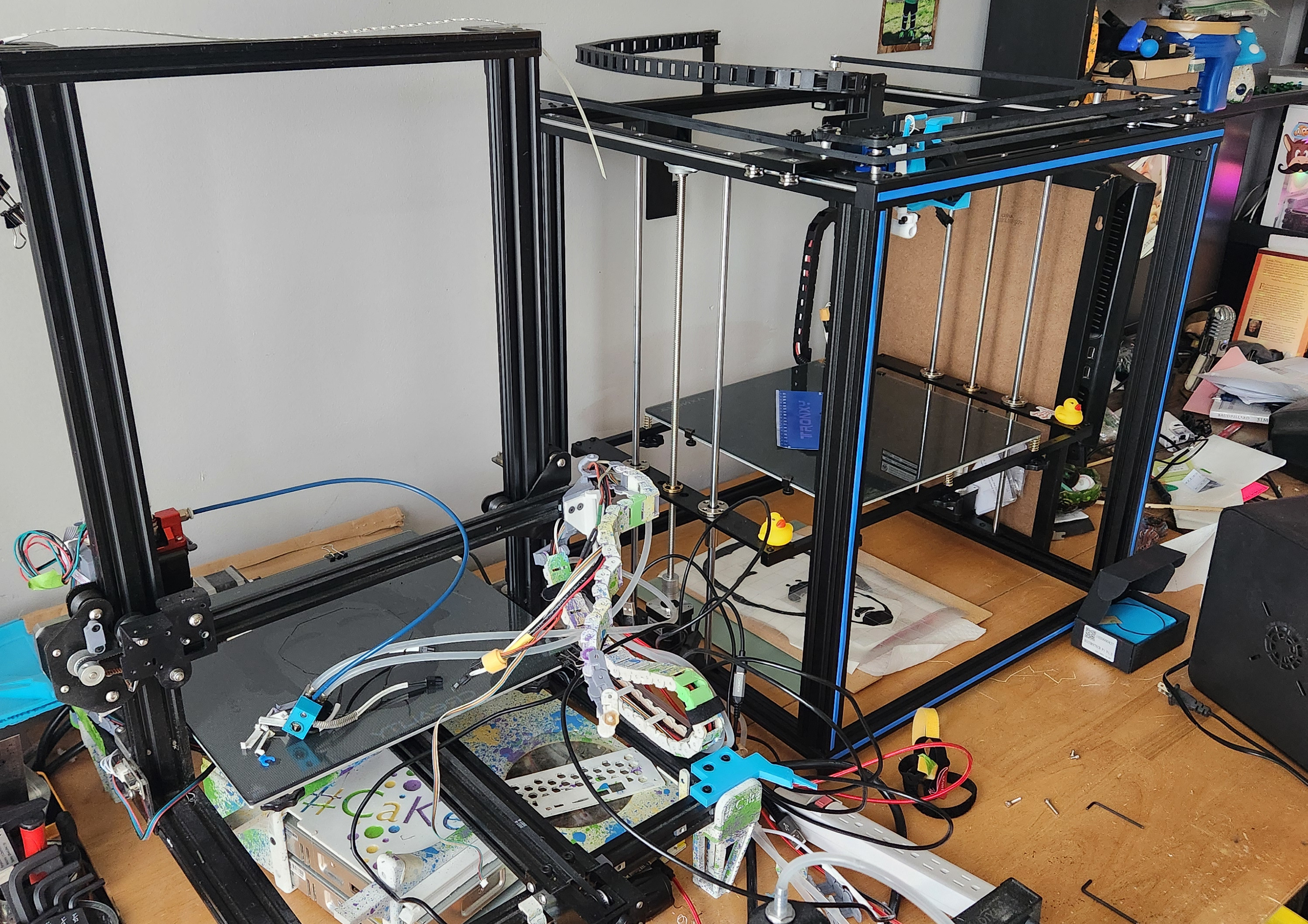

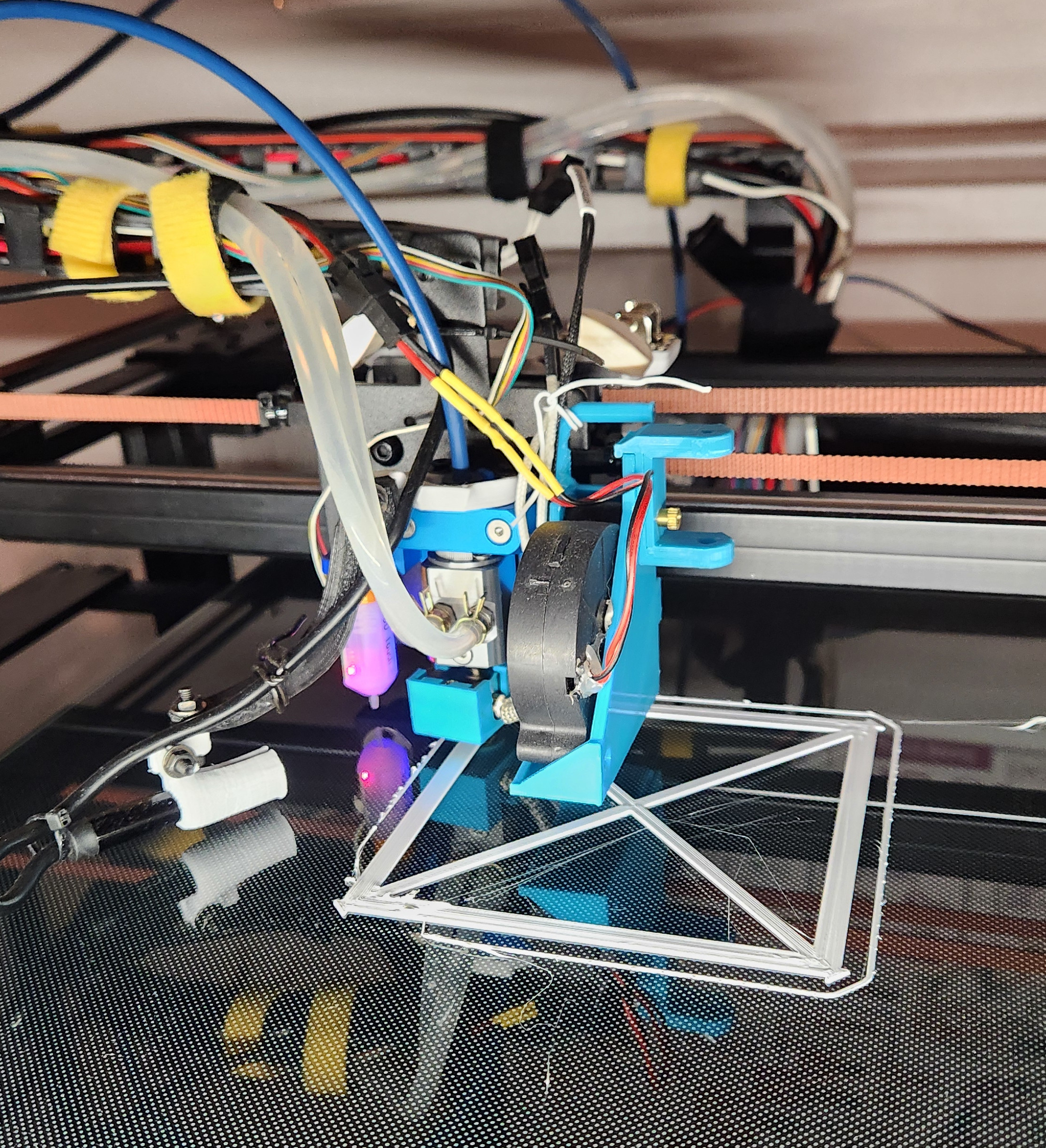

#CAKE, The Corexy Machine

This printer is built on a tronxy x5 pro frame. I decided to not install the stock electronics, and instead used the board and hotend from my larger cartesian printer. Customisations featuring:

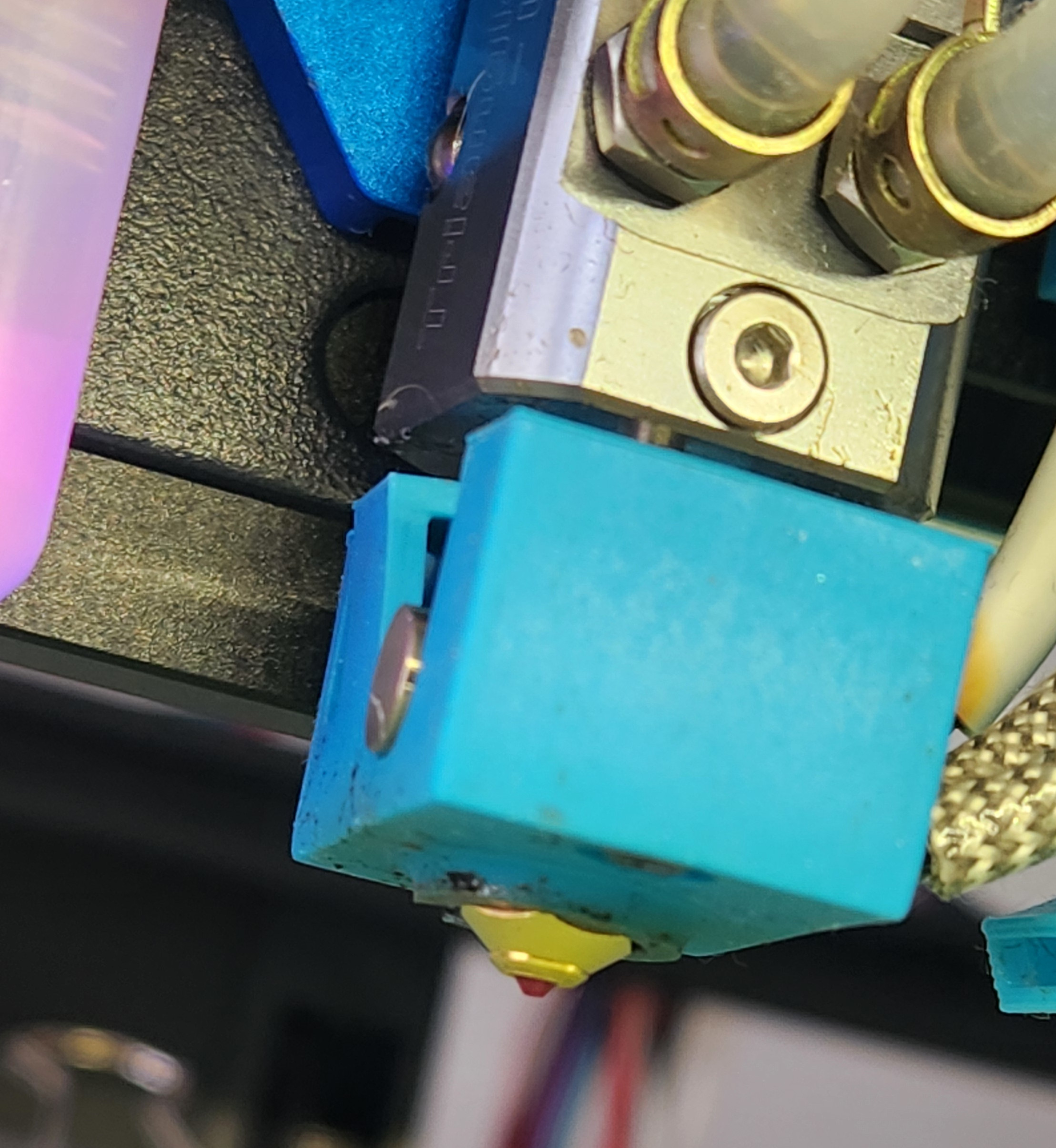

-Water cooled hotend (up to 600c) with a MAX31865 and PT1000 temp sensor

-Octopus pro mainboard

-klipper firmware

-BTT Pi v1.2

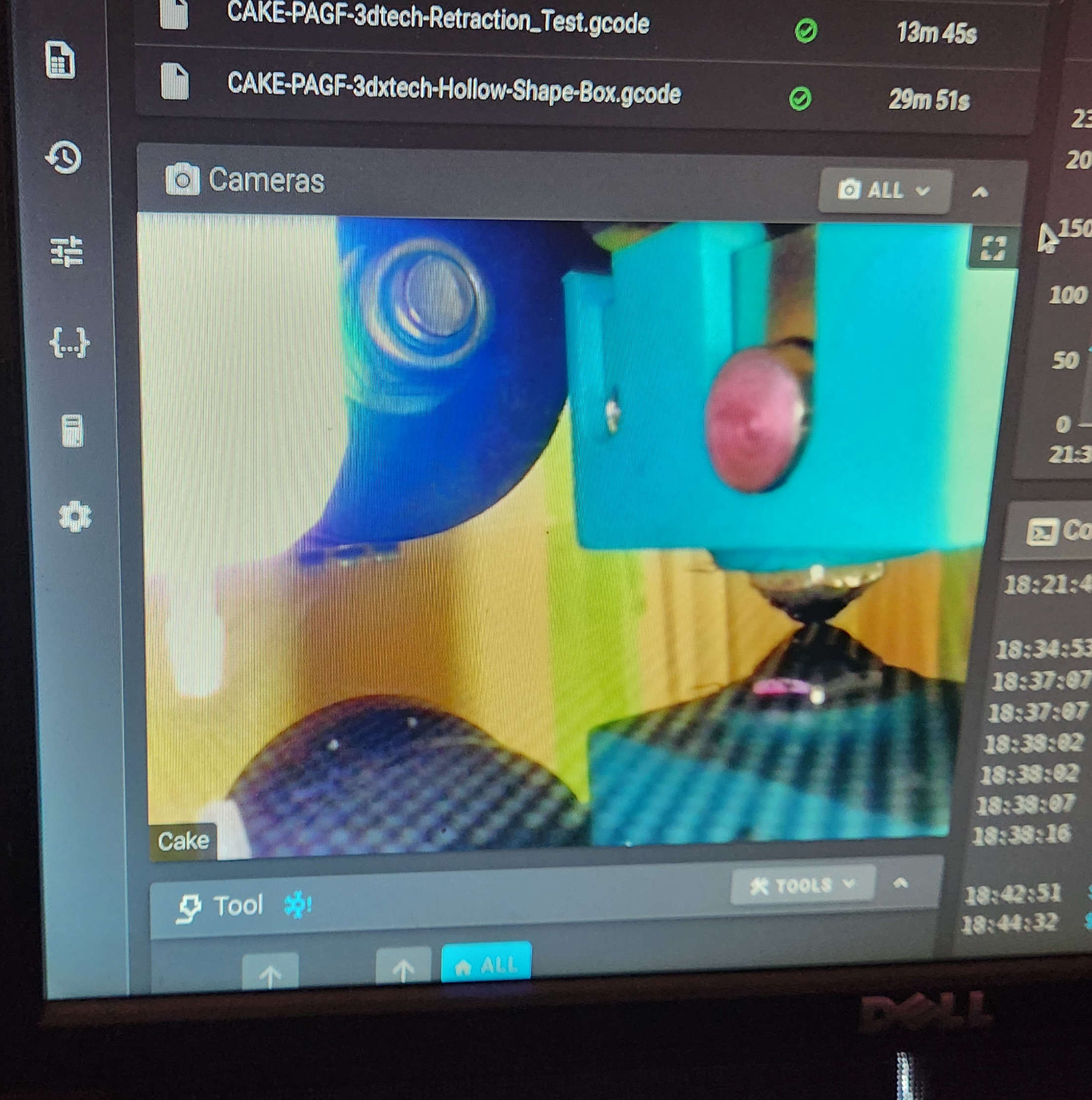

-Klipper screen, and Fluid web-interface

-dual 350 watt power supplies

-NozzleCam(tm) - mounted to the x carriage

-LED illuminated print area

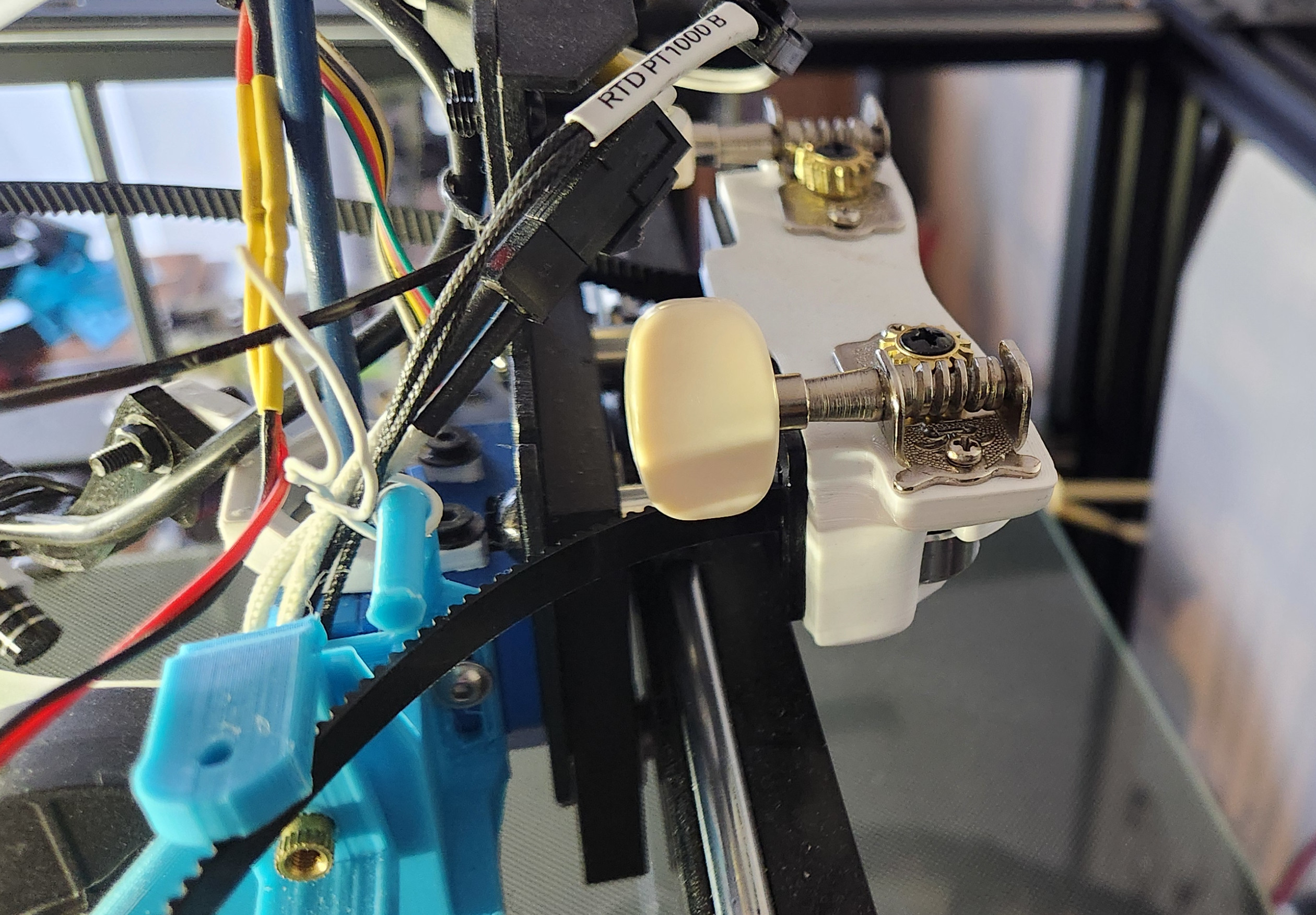

-Precision adjustable belt tensioner

-Ruby Nozzle